- #CNC SIMULATOR HAAS VERIFICATION#

- #CNC SIMULATOR HAAS SOFTWARE#

- #CNC SIMULATOR HAAS CODE#

- #CNC SIMULATOR HAAS FREE#

“First, we need to go out there and show that we can do the job, that we can finish races, that we are respected by the fans and other teams in the paddock. “Our goal with this car is to score points,” Steiner states. And our technical partner, Ferrari, provided our power unit, and that really defined the rear end of the car and how big it needed to be. UPC: PRODUCT ID: HM92364 Condition: Used. Simulation includes a number of configured machines including, Haas. Haas Cnc Control Simulator Csm2A Lathe W/ 32-3092F 4023R3201M Board. “We have very experienced designers who worked hard to develop all the little things from an aerodynamic perspective that, collectively, add up to a lot. Prove-out your NC program on a 3D model of your CNC machine and see the exact. “We’re a new team, so we looked at what the successful teams were doing to give us a baseline of the direction we needed to go with our design. “Just as Haas Automation’s products continually evolve, becoming better and more efficient, our methodology behind the VF-16 was to make it the best evolution of a good F1 car,” said Haas team principal Guenther Steiner.

The dark gray, light gray and red-toned livery of the VF-16 was also derived from Haas Automation’s machine tool lineage. Gene Haas, founder of Haas Automation, added “F1” to the name to unofficially designate it as the company’s “Very First One”. The “V” stands for vertical, which is an industry standard designation for a vertical mill. The F3 and F4 buttons on these newer controls provide the speed control, whilst the functions previously associated with them (as above) are no longer required, as the program and positions are displayed permanently in graphics mode.The new machine, which will be handed its official track debut when pre-season testing gets underway at Barcelona on Monday, is the results of more than two years of effort by Haas, who will become the first American team on the grid for 30 years.Īccording to the team, the origin of naming the car “VF-16” goes back to the first CNC machine manufactured by Haas Automation, the VF-1, launched in 1988. More recently, Haas controls have included the capability to alter the speed at which the graphic simulation is run, thus allowing the user to review slowly the particular area of concern before running through other sections at a much higher speed.

#CNC SIMULATOR HAAS CODE#

It allows the user to simulate all the CNC machine operations and debug NC code using the same platform Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines.

#CNC SIMULATOR HAAS VERIFICATION#

With the most accurate collision-detection. Swansoft CNC Simulator is real-time 3D CNC machine system simulation and advanced G-code verification software.

#CNC SIMULATOR HAAS SOFTWARE#

A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A).

#CNC SIMULATOR HAAS FREE#

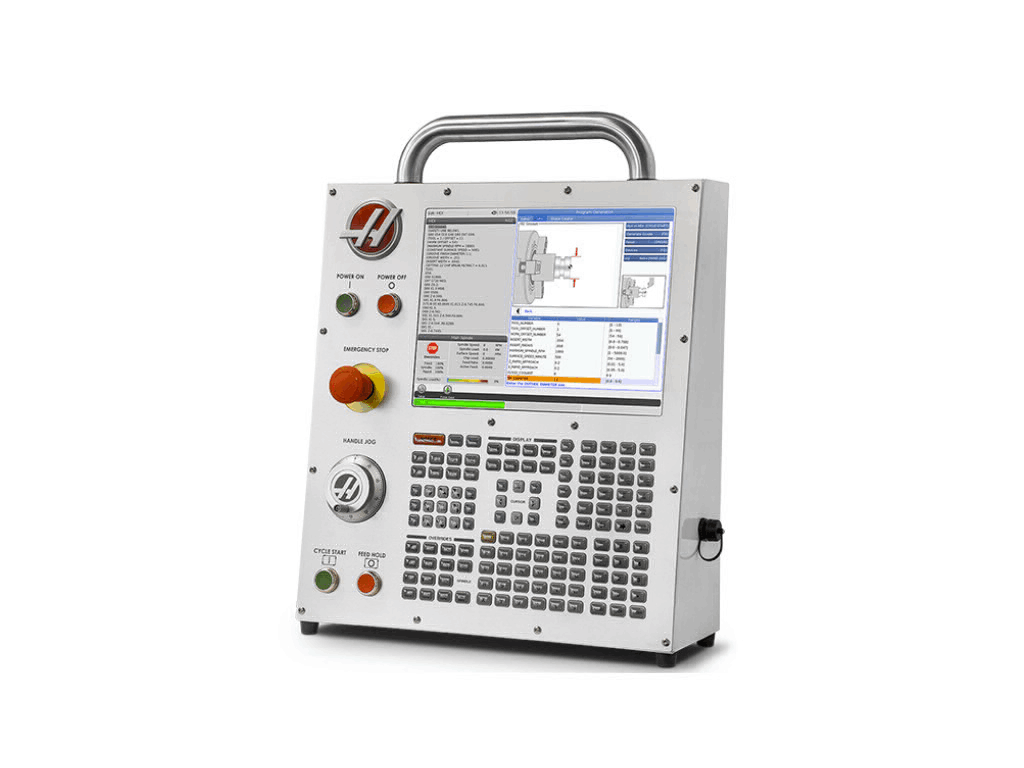

The Haas graphics system not only provides a graphical representation of the current program, but tests the program at the same time – looking for missing feedrates, syntax errors in the code and so on. VERICUT enables you to perform realistic 3D simulation of entire CNC machines, just like they behave in the shop. CNC Simulator Free - Apps on Google Play (Added 7 minutes ago) CNC Simulator Free. Alternatively, the user can press F3 key to change the position display, or the F4 key to display the current program and then pressing Cycle Start commences the ‘running’ of the program in the graphics display. Includes simulated dry run graphics, tool length measurement, true DNC and USB convenience. Use the Haas Control Simulator for classroom training and/or on-site control demonstrations with a real, fully upgradable Haas control panel and keypad. At this point, the user could then select F2 for the Zoom function using PAGE UP or PAGE DOWN to control the level of zoom. Low-cost Haas CNC Control Simulators are an excellent addition to any CNC training program. This was easily activated by pressing the MEM button to put the control into Memory mode and then pressing SETNG/GRAPH key to enter the Graphics display. Ever since the very first Haas control was built, the system has been capable of providing a graphical simulation for the user’s programs.

0 kommentar(er)

0 kommentar(er)